Discover the cutting-edge world of additive manufacturing with 3D Systems Inc., a leading company in the field of 3D printing services and rapid prototyping solutions. With their innovative technology and expertise, they have revolutionized product development and manufacturing processes, offering comprehensive solutions for a wide range of industries.

At 3D Systems Inc., they understand the power of 3D printing technology and its potential to transform the way we create and build. With their advanced industrial 3D printing capabilities, state-of-the-art design software, and a variety of printing materials, they provide tailor-made solutions to meet every additive manufacturing need.

Whether you are looking to create intricate prototypes, optimize production workflows, or explore new design possibilities, 3D Systems Inc. has the expertise and resources to support you at every step of the way. Their aim is to accelerate time-to-market, unleash design innovation, and optimize costs, giving you a competitive edge in the market.

Key Takeaways:

- 3D Systems Inc. is a pioneering additive manufacturing company.

- They offer a wide range of 3D printing services and rapid prototyping solutions.

- With their industrial 3D printing capabilities and advanced design software, they cater to various industries.

- 3D Systems Inc. aims to accelerate time-to-market, unleash design innovation, and optimize costs for their customers.

- Stay tuned to discover more about 3D Systems Inc.’s innovative solutions and success stories in additive manufacturing.

The Application Innovation Group

At 3D Systems, we understand the unique challenges that come with additive manufacturing. That’s why we have the Application Innovation Group, a team of experienced engineers and experts dedicated to helping our customers overcome these challenges and unlock the full potential of this transformative technology.

With decades of experience across industries such as aerospace and defense, automotive and motorsports, dental, jewelry, medical devices, and semiconductor, our Application Innovation Group has the knowledge and expertise to provide tailored solutions for your specific application needs.

Whether you’re in aerospace and defense, looking to optimize manufacturing processes and reduce part weight, or in dental, seeking to improve patient outcomes with customized dental solutions, our team is here to support you every step of the way.

Working closely with our customers, we collaborate to understand their unique requirements and provide tailored solutions that address their specific challenges. This includes hardware, materials, software, and services tools that accelerate product development and enable efficient production workflows.

By leveraging our Application Innovation Group’s expertise and comprehensive solutions, you can overcome the hurdles of additive manufacturing and achieve greater innovation, efficiency, and agility in your industry.

To give you a better understanding of our expertise and capabilities, here are some examples of the industries we serve:

- Aerospace and Defense: From lightweight components to complex geometries, our tailored solutions provide the aerospace and defense industry with the tools they need to enhance performance and drive innovation in manufacturing.

- Automotive and Motorsports: We help automotive and motorsports manufacturers accelerate prototyping, improve production processes, and create high-performance, customized parts with our additive manufacturing solutions.

- Dental: With our expertise in dental applications, we enable dental professionals to deliver highly accurate and customized solutions, from patient-specific implants to clear aligners, revolutionizing the field of dentistry.

- Jewelry: Our tailored solutions for jewelry manufacturers allow for intricate designs, faster production, and customization opportunities, empowering jewelers to bring their creative visions to life.

- Medical Devices: We collaborate with medical device manufacturers to develop patient-specific implants, surgical guides, and other innovative solutions that improve patient outcomes and redefine medical device production.

- Semiconductor: Our additive manufacturing solutions enable semiconductor manufacturers to produce complex geometries and prototypes faster, accelerating the development and testing of new semiconductor technologies.

No matter what industry you’re in, our Application Innovation Group is committed to providing you with the tailored solutions you need to overcome additive manufacturing challenges and drive innovation.

Contact us today to explore how our Application Innovation Group can help you unlock the full potential of additive manufacturing in your industry.

Professional Services

At 3D Systems, we understand that every organization faces unique design and manufacturing challenges. That’s why we offer professional services tailored to address these specific problems. Our team of experts possesses deep technical knowledge and extensive experience in additive manufacturing, allowing us to provide bespoke solutions that meet your exact requirements.

Throughout your application and organization journey, we are committed to providing comprehensive support. From the initial stages of exploration to the implementation and beyond, our professionals work closely with you to ensure a seamless and successful transition to additive manufacturing. With our guidance, you can tackle even the most complex problems with confidence.

As a key user of our own solutions, we not only possess technical expertise but also a practical understanding of real-world applications. This unique perspective enables us to offer valuable insights and recommendations that can help you accelerate time to market, mitigate risks, and maximize your return on investment.

Our professional services include:

- Design optimization and analysis

- Material selection and compatibility assessment

- Process optimization and workflow integration

- Post-processing and finishing techniques

- Quality control and validation

“The professional services offered by 3D Systems have been instrumental in overcoming our most challenging design and manufacturing problems. Their deep technical knowledge and dedication to delivering bespoke solutions have greatly benefited our organization.”

John Smith, CEO of XYZ Manufacturing

Partner with 3D Systems and gain access to our professional services that combine technical excellence with practical expertise. Let us support you throughout your additive manufacturing journey and provide the solutions you need to succeed.

Expertise and Support:

Our team brings a wealth of expertise in additive manufacturing and a commitment to supporting our customers at every step of their journey. We offer:

| Deep Technical Knowledge | Real-World Application Understanding | Comprehensive Solutions |

|---|---|---|

| Our team possesses deep technical knowledge in a wide range of additive manufacturing processes and technologies. We stay up to date with the latest advancements and bring this expertise to every project. | We have a practical understanding of real-world applications and the challenges our customers face. By leveraging our knowledge and experience, we can provide tailored solutions that address your specific needs. | With a comprehensive portfolio of 3D printers, materials, software, and services, we offer end-to-end solutions for additive manufacturing. Our goal is to provide everything you need to succeed in implementing additive manufacturing in your organization. |

Additive Manufacturing Journey

Embarking on an additive manufacturing journey can be a transformative experience for businesses. It involves a series of crucial stages, from exploration to scale, that require expert guidance and comprehensive solutions. At 3D Systems, we are committed to supporting our customers throughout every step of their additive manufacturing journey.

Exploration: Unveiling the Possibilities

When businesses first delve into additive manufacturing, they often find themselves in a realm of endless possibilities. Our team of experts is here to assist them in exploring the technology, understanding its capabilities, and identifying potential applications for their industry. We provide valuable insights and guidance to help businesses uncover the untapped potential of additive manufacturing and spark innovation within their organization.

Implementation: Integrating Additive Manufacturing

Once businesses decide to implement additive manufacturing in their workflows, they face the challenge of seamlessly integrating it into existing processes. Our comprehensive range of solutions, including advanced 3D printers, materials, and software, empowers businesses to effectively incorporate additive manufacturing into their production workflows. We provide the necessary tools and support to ensure a smooth transition and maximize the benefits of this cutting-edge technology.

Qualification: Ensuring Quality and Compliance

Qualification is a critical phase in the additive manufacturing journey as it involves validating processes and ensuring quality and compliance with industry standards. Our team of experts assists businesses in qualifying their additive manufacturing processes, particularly for applications in highly regulated industries such as medical, energy, aerospace, and defense. We provide the expertise and guidance to help businesses navigate the qualification process and achieve the highest standards of quality and compliance.

Scale: Accelerating Production

As businesses witness the success and benefits of additive manufacturing, they often seek to scale up their production. Our comprehensive approach covers not only the exploration, implementation, and qualification stages but also the necessary resources and strategies for scaling additive manufacturing operations. We offer tailored solutions to help businesses meet the increasing demands of their industry, accelerate production, and achieve sustainable growth.

Throughout the additive manufacturing journey, businesses can rely on 3D Systems to provide the guidance, expertise, and comprehensive solutions needed to achieve their goals and realize the full potential of additive manufacturing.

Comprehensive Solutions Portfolio

At 3D Systems, we pride ourselves on offering comprehensive solutions tailored to meet the diverse needs of our customers in the additive manufacturing space. With our wide range of offerings, we strive to provide everything our customers require for successful 3D printing projects.

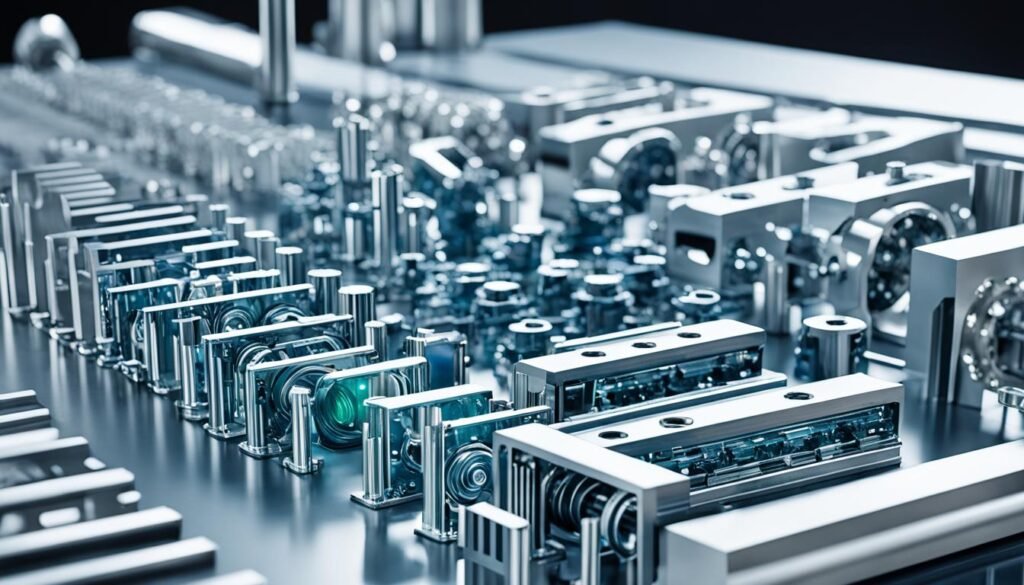

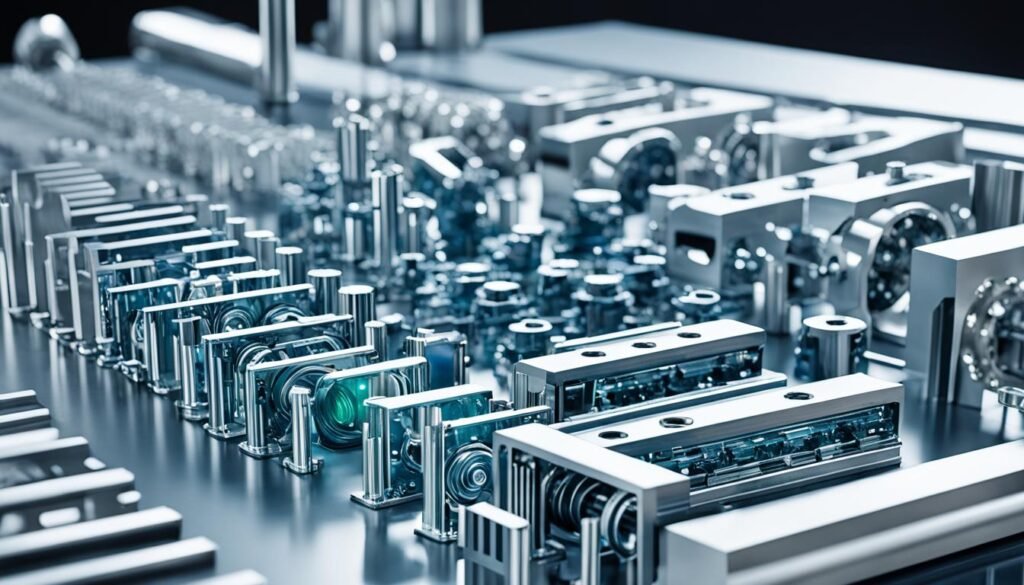

Our portfolio includes a variety of top-of-the-line 3D printers that cater to different applications, ensuring that we have the right printer for every need. Whether you’re working with metal, plastic, or wax, our printers deliver exceptional quality and precision.

But it doesn’t stop at printers. We also provide an extensive selection of materials specifically formulated to meet the unique requirements of different industries. From robust metals to flexible plastics, our materials deliver outstanding performance and reliability.

In addition to hardware and materials, we offer a range of software solutions designed to streamline workflow management and optimize printing processes. Our software solutions make it easier than ever to design, simulate, and optimize your 3D printing projects.

And to ensure our customers receive the support and expertise they need, we have a team of applications experts ready to provide guidance and assistance. Whether it’s choosing the right materials, optimizing design files, or troubleshooting any challenges along the way, our experts are here to help.

Furthermore, we understand the importance of advanced manufacturing capabilities, and that’s why we offer an array of services to help our customers take their additive manufacturing to the next level. From design assistance to production support, we have the resources and expertise to make your project a success.

In summary, our comprehensive solutions portfolio encompasses 3D printers, materials, software, services, and applications experts. We are committed to providing our customers with the tools and support they need to excel in advanced manufacturing. Whether you’re a small business venturing into 3D printing for the first time or a large organization looking to optimize your additive manufacturing processes, 3D Systems has the comprehensive solutions you need to succeed.

Application Innovation Group Support

In the realm of additive manufacturing, validation and qualification support is crucial, especially for critical applications in highly regulated industries such as medical, energy, aerospace, and defense. That’s where 3D Systems’ Application Innovation Group comes in.

With their expertise and deep understanding of the intricacies of these industries, the Application Innovation Group is dedicated to providing the necessary support to accelerate the pathway to AM production. They assist customers in ensuring compliance and efficiency in their production workflows, paving the way for successful additive manufacturing implementation.

“The Application Innovation Group at 3D Systems has been instrumental in helping us navigate the validation and qualification challenges in the aerospace industry. Their support has been invaluable in accelerating our AM production processes.” – John Smith, Aerospace Engineer

By leveraging their extensive experience and collaborating closely with customers, the Application Innovation Group tailors solutions to meet specific validation and qualification requirements. From designing optimal workflows to addressing technical challenges, their support accelerates the adoption and implementation of additive manufacturing technologies.

Through rigorous validation and qualification processes, the Application Innovation Group ensures that critical applications are optimized for performance, quality, and safety. By validating and qualifying additive manufacturing processes, they provide the necessary assurance to meet stringent industry standards and regulations.

With the support of the Application Innovation Group, customers can confidently integrate additive manufacturing into their production workflows, unlocking the numerous benefits of this transformative technology.

Validation and Qualification Support

The Application Innovation Group offers comprehensive validation and qualification support to verify the performance, reliability, and consistency of additive manufacturing processes. They assist customers in conducting test protocols, collecting and analyzing data, and ensuring that production outcomes meet the highest quality standards.

Accelerating Pathway to AM Production

By working closely with customers, the Application Innovation Group accelerates the pathway to AM production. Through their expert guidance and support, they streamline workflows, identify production bottlenecks, and optimize processes to achieve efficient and cost-effective additive manufacturing production.

| Benefits of Application Innovation Group Support |

|---|

| Validation and qualification expertise for critical applications |

| Streamlined production workflow for optimal efficiency |

| Assurance of compliance with industry standards and regulations |

| Accelerated implementation of additive manufacturing technologies |

The Application Innovation Group at 3D Systems plays a vital role in supporting customers throughout their additive manufacturing journey, enabling them to overcome challenges, validate processes, and qualify critical applications. With their assistance, customers can confidently accelerate their pathway to AM production, driving innovation and success in their industries.

Latest News and Customer Success Stories

Stay updated with the latest achievements and collaborations of 3D Systems Inc. We are excited to share our recent accomplishments and customer success stories that demonstrate the impact and potential of our innovative solutions.

“The National Medal of Technology and Innovation Award”

One of our proudest moments was when Chuck Hull, our co-founder and chief technology officer, was honored with the National Medal of Technology and Innovation. This prestigious recognition underscores our commitment to pushing the boundaries of additive manufacturing and driving technological advancements in the industry.

“Icon Technologies Limited – Revolutionizing Thermoforming Mold Production”

Our collaboration with Icon Technologies Limited has revolutionized the field of thermoforming mold production. By leveraging our cutting-edge 3D printing technology, Icon Technologies Limited was able to enhance mold design, reduce production time, and bring innovative products to market faster than ever before.

“Transforming Lives with Patient-Specific 3D-Printed Implants”

In the field of medical applications, we have witnessed remarkable success stories with the use of our patient-specific 3D-printed implants in cranial surgeries. By utilizing advanced 3D modeling and printing technologies, we have been able to provide personalized and precise solutions that optimize patient outcomes and recovery.

These collaborative efforts and customer success stories exemplify the diverse applications and transformative capabilities of 3D Systems’ solutions across industries. We remain committed to driving innovation, empowering our customers, and unlocking the full potential of additive manufacturing.

3D Printing Resources

At 3D Systems, we believe in empowering our customers with knowledge and tools to fully utilize the potential of 3D printing technology. Our range of resources is designed to educate and inform, enabling you to make informed decisions and maximize the benefits of additive manufacturing.

Webinars

Explore the endless possibilities of 3D printing through our informative webinars.

Join our webinars where we cover a wide range of topics, including customer applications, solutions, products, and services. Our industry experts share valuable insights and best practices, helping you stay up-to-date with the latest trends in additive manufacturing. Whether you are new to 3D printing or looking to enhance your existing knowledge, our webinars are a great resource for expanding your understanding of this transformative technology.

Buyer’s Guide

Discover the right 3D printing technology for your specific needs.

Choosing the most suitable 3D printing technology can be a daunting task with the numerous options available. Our comprehensive buyer’s guide provides you with detailed information on the different types of 3D printing technologies, materials, and applications. We break down the pros and cons of each technology, empowering you to make an informed decision that aligns with your requirements and goals.

3DXpert Software

Unleash your design potential with our powerful 3DXpert software.

3DXpert is our advanced design software that expands the design envelope, accelerates design cycles, and unlocks new applications. With its intuitive interface and robust features, 3DXpert allows you to optimize your designs for additive manufacturing, ensuring efficient workflows and superior end results. Whether you are a novice or an experienced designer, our software provides the tools you need to take your creations to the next level.

Careers at 3D Systems

If you’re looking to build a rewarding career in the additive manufacturing industry, 3D Systems offers exciting opportunities for professional growth. As a leading additive manufacturing solutions partner, we are constantly seeking talented individuals to join our team and contribute to the advancement of this innovative technology.

At 3D Systems, we provide a dynamic and innovative work environment that fosters creativity and collaboration. Our employees have the opportunity to work with cutting-edge technologies, collaborate with industry experts, and make a meaningful impact in the additive manufacturing industry.

As an additive manufacturing solutions partner, our focus is on providing comprehensive and tailored solutions to our customers. This requires a diverse and talented workforce with expertise in various areas, including engineering, software development, materials science, and more. We value diversity and are committed to creating an inclusive work environment where everyone can thrive.

Why Choose a Career at 3D Systems?

- Opportunity for Growth: 3D Systems is a global leader in additive manufacturing, and joining our team means being part of a fast-growing industry. As the technology continues to advance, there are endless opportunities for learning, development, and career progression.

- Meaningful Impact: Additive manufacturing has the potential to revolutionize industries and transform the way products are designed and manufactured. Joining 3D Systems allows you to be at the forefront of this innovation, making a difference in various industries and contributing to the future of manufacturing.

- Collaborative Environment: At 3D Systems, we believe in the power of collaboration. Our teams work closely together, leveraging their expertise to solve complex challenges and deliver the best solutions to our customers. You’ll have the opportunity to collaborate with industry leaders, share knowledge, and learn from the best in the field.

- Employee Development: We are committed to helping our employees reach their full potential. Whether it’s through training programs, mentorship opportunities, or ongoing learning initiatives, we invest in our employees’ professional development to ensure they have the skills and knowledge they need to succeed.

Join the 3D Systems team and embark on an exciting career in additive manufacturing. Together, we can shape the future of manufacturing and drive innovation in this dynamic and rapidly growing industry.

Conclusion

In conclusion, 3D Systems Inc. is a leader in additive manufacturing innovation. Their comprehensive solutions, industry expertise, and dedication to customer success have established them as a trusted partner for organizations who want to harness the benefits of 3D printing and rapid prototyping. With a wide range of 3D printers, materials, software, and services, they empower businesses across industries to explore new possibilities and drive innovation in product development and manufacturing.

By pushing the boundaries of additive manufacturing, 3D Systems is unlocking the full potential of 3D printing technology. Their commitment to continuous improvement and staying at the forefront of the industry ensures that their customers have access to the latest advancements and cutting-edge solutions. Whether you are a small business or a large corporation, 3D Systems has the expertise and resources to support your additive manufacturing journey.

Choose 3D Systems Inc. as your additive manufacturing partner and benefit from their industry-leading solutions, deep technical knowledge, and commitment to customer success. They are dedicated to helping you accelerate time-to-market, drive innovation, and optimize costs through the power of 3D printing and rapid prototyping. Join the additive manufacturing revolution with 3D Systems and unlock a world of possibilities for your business.

FAQ

What is 3D Systems Inc.?

3D Systems Inc. is a pioneering company in the field of additive manufacturing, specializing in 3D printing services and rapid prototyping solutions.

What industries does the Application Innovation Group cater to?

The Application Innovation Group caters to various industries such as aerospace and defense, automotive and motorsports, dental, jewelry, medical devices, and semiconductor.

How does 3D Systems provide support for challenging design and manufacturing problems?

3D Systems offers professional services and bespoke solutions to support customers throughout their additive manufacturing journey. Their team provides guidance and support based on their deep technical knowledge and understanding of real-world applications.

Does 3D Systems support customers at all stages of the additive manufacturing journey?

Yes, 3D Systems supports customers at all stages of the additive manufacturing journey, whether they are exploring the technology, implementing it in their workflows, qualifying the processes, or scaling up production.

What does the comprehensive solutions portfolio of 3D Systems include?

The comprehensive solutions portfolio of 3D Systems includes a wide range of 3D printers for different applications, a variety of materials specifically formulated for different needs, software solutions for workflow management and printing processes, and services provided by applications experts and advanced manufacturing capabilities.

How does the Application Innovation Group provide support for validation and qualification?

The Application Innovation Group provides support for the validation and qualification of additive manufacturing processes, particularly for critical applications in highly regulated industries such as medical, energy, aerospace, and defense.

What news and updates does 3D Systems regularly share?

3D Systems regularly shares the latest news and updates on their achievements and collaborations, such as awards received by their co-founder and chief technology officer and customer success stories showcasing the impact of their solutions in various industries.

What resources does 3D Systems provide to educate customers about 3D printing?

3D Systems provides webinars covering customer applications, solutions, products, and services, a buyer’s guide for learning about different 3D printing technologies, and promotes their 3DXpert software for expanding the design envelope and unlocking new applications.

Are there career opportunities available at 3D Systems?

Yes, 3D Systems offers exciting career opportunities for individuals looking to grow professionally in the additive manufacturing industry and contribute to the advancement of additive manufacturing technology.

What are the key highlights of 3D Systems Inc.?

3D Systems Inc. is a leading additive manufacturing company that offers comprehensive solutions, industry expertise, and a commitment to customer success, empowering organizations to leverage the benefits of 3D printing and rapid prototyping.